Some controllers are purpose-built with only a specific application in mind. While others, like ControlByWeb (CBW) modules, are built with flexibility as a priority. We manufacture controllers that are incredibly flexible and configurable while maintaining the simplest user interface in the industry. The result is a much shorter time to project completion and easy integration with control systems.

This is a design choice we made many years ago. Our philosophy has always been to simplify industrial control hardware and the process of deploying and integrating systems. Our very first industrial controller, released in 2004, featured an open REST API for easy remote access, control, and software integration.

With today’s CBW controllers, you have a feature-rich platform of smart I/O controllers built for IoT applications at the edge.

How ControlByWeb® Controllers Are Used

Outside of the many individual use cases and applications of our controllers, there are three main categories, or application types, where our controllers shine:

- Stand-alone controllers

- Collaborating peer-to-peer as a micro control system

- An I/O card in a larger control system

These three different modes of operation are fairly distinct, and the features of a controller that make it good for one may not suit another type of application. This is a big reason why CBW is unique in the market. Our controllers are at home in such a wide variety of applications and industries because of the inherent flexibility we have designed into our modules.

Determine the best products for your application with our Sales Engineers.

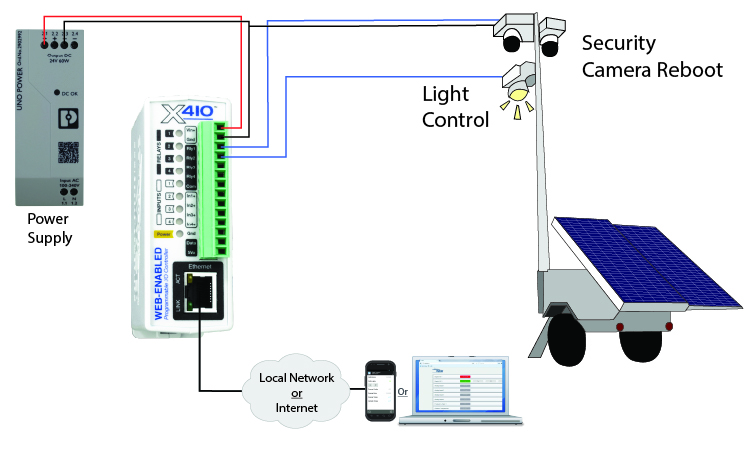

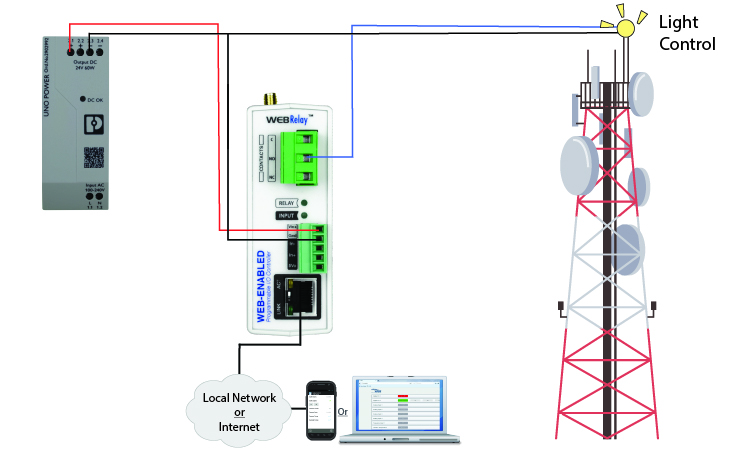

Stand-Alone Controllers

There are myriad situations when a single solution is needed for a fairly, if not completely, isolated monitoring or control task. Here are a few specific examples of use cases from our customers, though they won’t come close to covering all the possibilities:

- Monitoring tank level in a single water cistern at a hotel in a remote location

- Recording temperature and sending email alerts on a walk-in freezer

- Controlling an irrigation pump on a farm, orchard, or ranch

- Reporting fracking fluid flow through a meter on a delivery truck

- Automated rebooting of a modem on a radio tower, or as needed

The applications include monitoring one or a few inputs from sensors and contacts and perhaps controlling one or a few industrial appliances. While they may send data off to another system, they largely operate on their own, using embedded logic that is either scheduled or conditional.

Because most of our modules include both inputs and relays, with embedded logic, email tool, an open API, and industrial communication protocols, they work beautifully in stand-alone monitoring and control applications. These applications can be local or remote, but they are isolated either because integration into a system isn’t necessary, or there are few I/O endpoints.

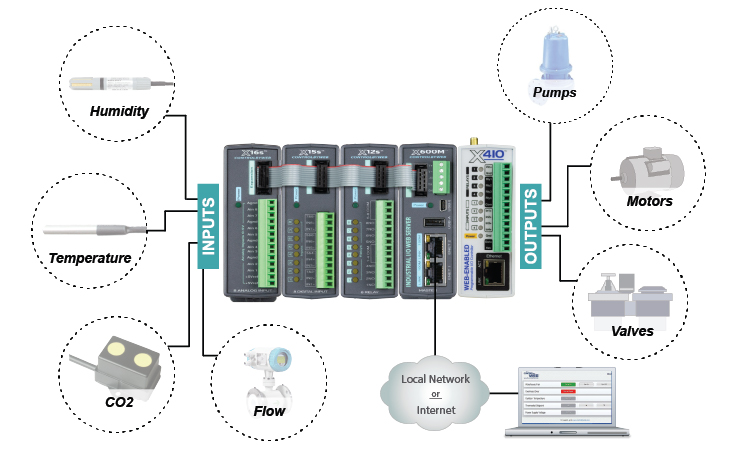

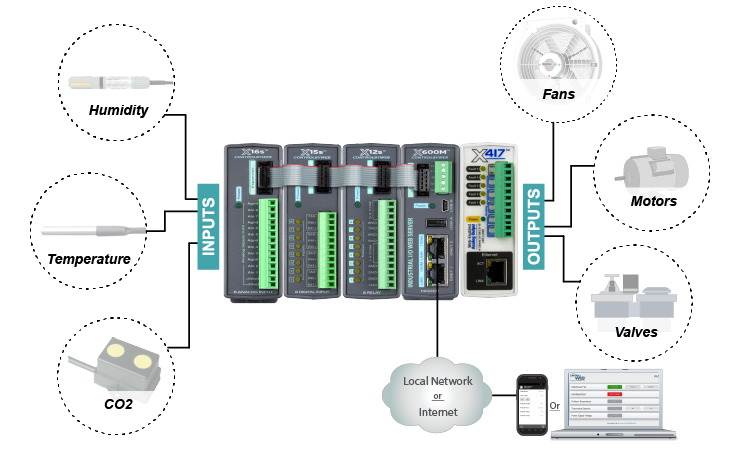

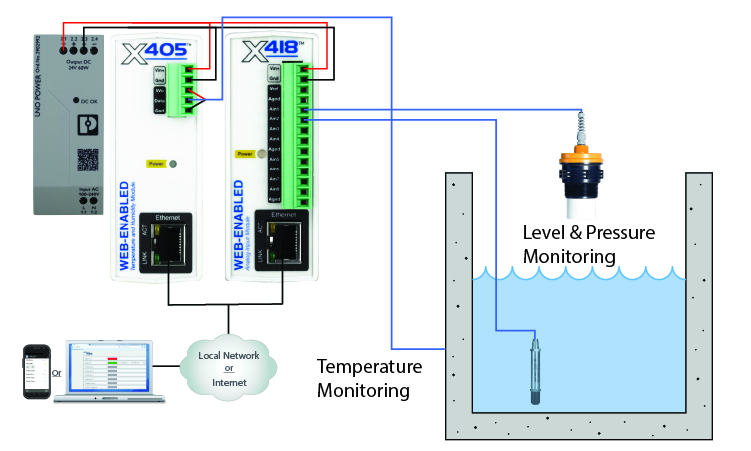

Micro Control Systems

When you need to do more than one or a very few things, and the application is still isolated, or stand-alone, then you will likely need multiple CBW controllers working together to form a simple, hardware-centric control system. Examples of this from our customers include:

- Sewage lift station monitoring and control

- Small greenhouse automation

- Temperature monitoring system and alarm management

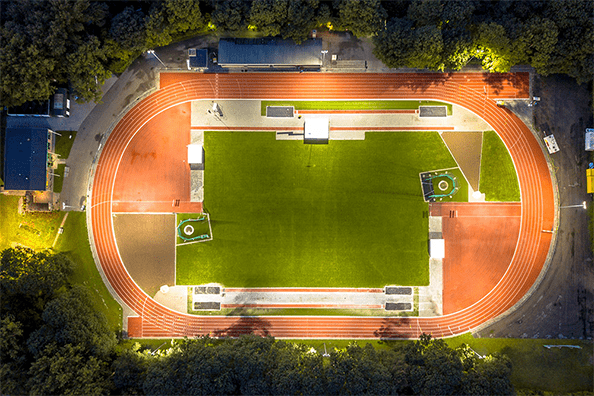

- Lighting control system

- Simple HVAC control system

These applications are simple in nature, involving if/then conditional logic or preprogrammed schedules, or even data logging and API calls. Not only are CBW modules well-suited for these kinds of applications, but they also communicate directly with each other over IP networks. This makes them particularly adept at coordinating to monitor process data and control a variety of industrial equipment.

This is possible without control software, even if not optimal (given unlimited resources), because of the embedded, browser-based user interface where you can program logic and control the interaction and I/O sharing between our controllers. This UI makes configuration and programming much easier. It also includes a dashboard that allows users to keep tabs on things like sensor data, I/O states, equipment status, etc.

CBW modules also include a data log, which can be accessed on the device, sent via email or FTP, and viewed on the optional ControlByWeb Cloud. This logging feature is very useful when running a small system with our controllers because it provides historical data for optimization and troubleshooting.

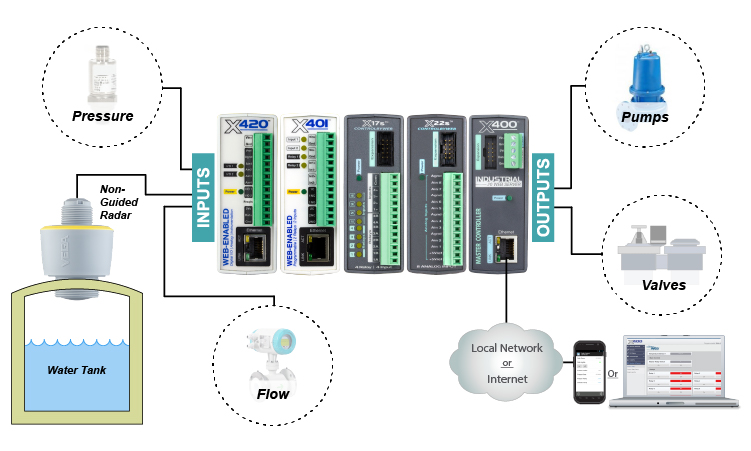

Part of a Larger Control System

For many applications, our controllers will be a small cog in a much larger machine. This is extremely common and our capable logic controllers fit perfectly in this role. There are a few features that make CBW devices great at control system integration:

- Open protocols such as MQTT, Modbus, SNMP, and a RESTful API

- Edge processing with embedded logic, including advanced scripting for redundancy or contingency operations

- Full device control for control software via protocols and API

This means our devices integrate smoothly with most control software and IoT platforms such as Ignition, TIA Portal, AVEVA, VTScada, Kepware, and others. Additionally, you have full control over how the device operates–either in edge processing mode where it uses embedded logic, or in worker mode where it receives all logical decisions from the control software and acts as a “dumb” I/O card.

It’s typical for a combination of the two modes to be used. Note, these modes are not settings in the device, but simply decisions you make as you configure. The device will respond to valid API calls and protocol commands, regardless of whether you have embedded logic programmed in the device.

Examples from our customers include:

- Industrial ventilation systems for long term storage facilities

- Load shedding systems for solar powered and battery-operated facilities

- Medical gas inventory management in a hospital

- Monitoring industrial press and cutting machines in a composites manufacturing plant

These applications vary wildly in complexity as does our role in them. While our devices can be used for any monitoring and control task, details take over here from electrical wiring requirements to signal and protocol details from equipment and sensors.

Our controllers work with digital (on/off), analog, and Modbus RS-485 signals from sensors and equipment. They also respond to commands from the protocols listed above. They also communicate peer-to-peer over any IP network, including cellular (via our optional cloud service), so you can use them to gather data and control relays at remote sites on your campus.

Unique Flexibility

We focus on providing flexibility for our customers. Our devices are built to be fully user-programmability with as few dependencies as possible. For example, here is a list of capabilities that are entirely optional:

- Software. Our devices are inherently browser-based, and that is how they’re configured or programmed. No software required. However, we integrate easily with third-party software and custom programs. The world is your oyster.

- Protocols. You can just communicate using our open REST API. Or you can use a popular protocol such as MQTT, Modbus, or SNMP. It’s up to you.

- Cloud. We built a cloud option for those who need it, but our controllers are built to network any which way you need.

- Embedded logic. Our controllers will respond to protocol commands and API requests without any logic programming on the device. You simply need to configure the networking and the basic protocol parameters.

- Scripting. Most of our devices can be programmed in BASIC, and the X-600M can be programmed using LUA. Writing script opens the capabilities of our controllers, allowing highly custom and flexible control scenarios. However, you can program logic using our pre-configured drop-down menus that include most triggers, actions, and scheduling options.

- Network connection. Once you set up the device, it will do its job with or without a network connection. If you configure it to log data, it will do so. If you program logic, it will dutifully carry out your instructions.

- External control system. CBW logic controllers are designed to work seamlessly with nearly any third-party control system. However, you can run these as a stand-alone device or system of devices.

ControlByWeb Case Studies

VTScada: Comprehensive Data Acquisition for IIoT Software

Valorence: Mobile Surveillance Systems

Industrial Ventilation Inc.: Agricultural Temperature & Humidity Control

LumenServe℠: Tower Light Monitoring & Remote Reboot

Industry Corps: Personalized Solutions for Industry 4.0

California Avacado Orchard: Smart Irrigation Automation

The ControlByWeb® Difference

We don’t box you into our way of doing things. These controllers are ideal for a broad array of applications in commercial and industrial settings. Purpose built just isn’t our philosophy.

We’d love to hear about your application. Chances are, we have a great option for you. Bring your application details and we’ll help you understand if our controllers are a good fit. Contact our team or schedule a 15-minute product demo.

Subscribe to Our Newsletter

Subscribe to Our Newsletter

Sign up for our newsletter to receive information regarding new products and exclusive offers.