It’s a relatable story for many ControlByWeb® customers: A system integrator discovers our hardware for a one-off solution. Then they start experimenting with the embedded UI, Task Builder, and scripting capability. Before long they’re using multiple controllers to impact operations and unlock valuable data visibility.

Jason is the Vice President of Engineering at a large international commercial and military aviation company. What started as straightforward environmental monitoring through our controllers has expanded to freezers, holding tanks, containment pits—all visualized through VTScada.

Determine the best products for your application with our Sales Engineers.

Reliable Temperature & Humidity Monitoring

Jason’s company has “layup rooms” that are used to treat metals. They bond hydroscopic adhesives to pallets, shelters, and containers that have undergone a special etching process. This curing method requires precision and needs to be monitored at all times—the adhesive is very costly. Jason needed a reliable solution to monitor both the curing and storage environments of these adhesives.

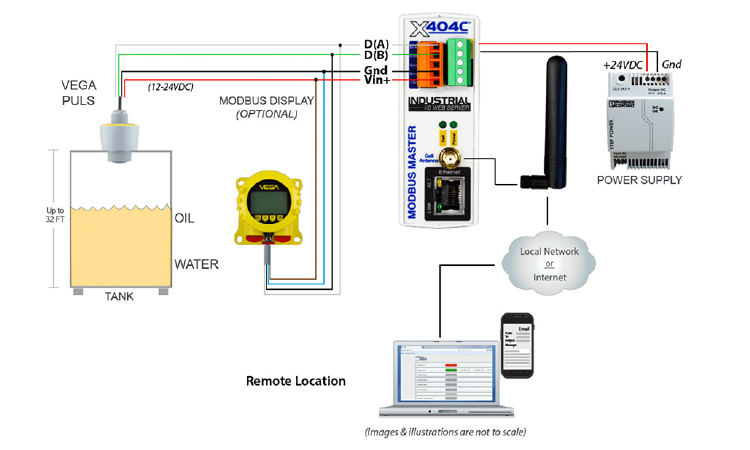

He initially chose ControlByWeb because of the easy integration with Modbus. (Our devices can convert data through equations for easy use in third-party systems.) The initial draw was that ControlByWeb was the only company offering a “Modbus-capable device with smarts.” The 400 Series were the “one-and-done” modules that could utilize one-wire and analog while simulating a digital signal.

Setting up the controller and connecting sensors was simple. So was working through Modbus to ultimately bridge to VTScada, a popular SCADA software. It’s here in VTScada where Jason was able to visualize the layup room’s ambient environment and, later, a separate freezer.

There’s additional brainpower, too—conditional logic on the X-405™ was created to send alerts when the temperature fluctuates outside of a certain threshold. Jason established low-level, high-critical alerts through the controller; an email is sent in the case of environmental red flags or if the SCADA software ever becomes unresponsive. In the event of an outage, being able to see real-time data and access historical data logs through the ControlByWeb module offers reassurance. (A built-in capacitor in the controllers also ensures no data is lost in the event of a total power outage.)

Setting up these notifications through the embedded UI led Jason to explore other uses for our devices.

“[ControlByWeb is] my first choice of product line.”

“I’ve been using ControlByWeb for about 8 years now. I can only think of a single hardware failure out of 100+ units installed in some really inhospitable places. Pre- and post-sales support has been excellent. My first choice of product line—I shoehorn them into any application where they can conceivably do the job.”

Expanding Logic at the Edge

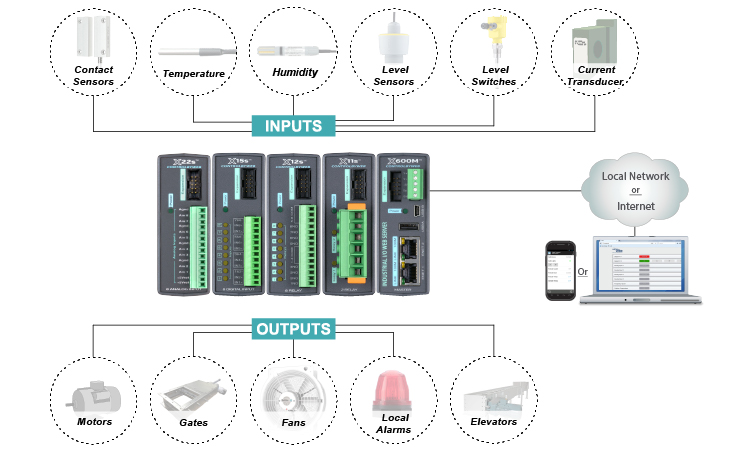

ControlByWeb controllers are perfectly suitable to act as simple data gateways or fully independent logical controllers. Jason was impressed with the flexibility of our devices to integrate with their existing infrastructure. “Your stuff has given me the chance to do relays, analog, digital—every type of data acquisition—and compress it all to Modbus to bring it into this [VTScada] system.” The modules’ versatility has allowed them to monitor a wide range of signals and ensure redundancy for critical alerts.

Jason faced several more edge data challenges across the company campuses beyond measuring the layup room environment. He needed solutions that were repeatable and scalable, and that could handle a wide range of data acquisition tech, including relays.

First, a one-wire temperature sensor was added to the existing X-405™ to monitor a freezer. Later, an X-600™ was integrated with several expansion modules to monitor holding tank level and flow to/from the tanks. There is also a containment pit where a variety of edge data is being captured.

Altogether, over a dozen of our units are bridging the gap to monitor water flow, temperature, tank level, CO2 discharge system, and flood sensors through VTScada, while offering local logic as necessary. If the central system goes down, Jason can control what’s happening in the room through our devices and open up a water bypass if necessary.

A Capable Future

Jason’s company continues to expand their offerings and partnerships—which means new opportunities to harness edge data. ControlByWeb is at the top of his mind: “Most rooms in our three campuses will have your [units] in them eventually.” A big reason for this is the team behind the products. In a highlight of the excellent support he’s received, Jason says, “I’ve emailed support a couple times and it’s been great. You guys have been awesome. This has been a really successful deployment so far and the backbone is your product.”

The successful implementation of ControlByWeb’s modules has significantly improved their monitoring and control processes. The versatility, reliability, and have made the products an invaluable asset.