It’s shocking, and somewhat encouraging, how many aging PLCs are still in operation today. A testament to modern engineering, a lot of PLCs from the 90s are still chugging along. Many from past decades are losing support from manufacturers, entering their inevitable end-of-life stage.

This leaves end users to ask: What is the best way to replace this old PLC?

The good news is that you likely don’t need a new PLC, or programmable logic controller. Microprocessor technology has advanced at breakneck pace, and smaller, simpler controllers are often capable of the same functionality as older systems that were once considered advanced. The cost to upgrade might be lower than you think.

Do You Need a PLC?

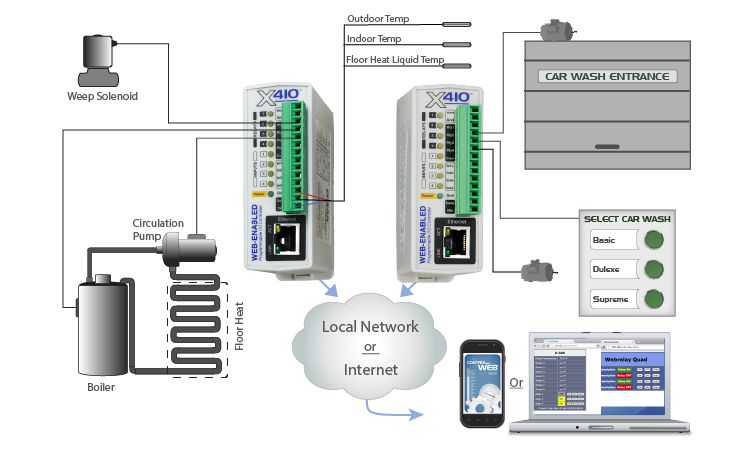

You might be surprised to learn that the trusty PLC isn’t always the answer. Many of our customers use our 400 and 600 Series ControlByWeb® logic controllers at price points well below $1000 to replace legacy control systems, including PLCs. To their delight, our browser-based user interface provides a no-code configuration to build conditional and scheduled logic with ease. They can break their control needs down to a series of if-then statements or simple schedules—they don’t need the programmable muscle (or the price tag) of modern PLCs.

Others are moving all the brain power to the software layer, using programs like Ignition or VTScada, and others to build and run logic. In this case, our controllers are still a great fit, taking commands from the software via MQTT or our open API. There is a growing trend away from PLC-based control systems and towards a more flexible network of edge controllers and powerful centralized software.

Subscribe to Our Newsletter

Subscribe to Our Newsletter

Sign up for our newsletter to receive information regarding new products and exclusive offers.

Follow Us on Social

Aren’t ControlByWeb Controllers PLCs?

That’s a nuanced question. By most standards, not really. Here’s where it gets tricky, our devices are logic controllers that are programmable. But when most integrators and end users think of a PLC, they don’t typically think of a device like ours.

We offer a simple logic controller capable of handling surprising complexity. However, we don’t, and aren’t trying to, handle logarithmic control such as PID loops or other heavy mathematical logic.

Our IoT logic controllers are built for edge data acquisition and control, or edge processing. You can configure if-then logic using the built-in options in our task builder. The interface is simple to navigate, giving you drop-down menus to set triggers and actions. Or you can program them using BASIC code, an easy-to-learn script language. Especially when using BASIC, the if-then logic can get advanced, and the controllers have many built-in features to support advanced industrial use cases.

So, depending on how you define PLC, we may be what you think of. But we don’t make complex, industrial behemoths that require advanced programming from a specialized engineer. We make the easy-to-use kind that are optimized for Industry 4.0 and integration with modern control systems.

A Typical Use Case: Vacuum Pump Lead-Lag Control

One ControlByWeb customer uses vacuum pumps in a temperature-controlled clean room. The company manufactures custom parts out of composite materials for the aerospace and defense industries.

The pumps are critical to keep the clean rooms operational. One way to improve the pump lifespan is load balancing. One pump runs while the other rests. If there is additional load, or pump demand, the resting pump can kick in and boost the airflow. The logic is simple: track the runtime of each pump and when one gets too far ahead of the other, switch their roles. Another common term for this is lead-lag.

This customer had an aging PLC—so old that all the people who knew how to program it had moved on. Troubleshooting was very difficult, requiring a lot of research and trial and error. Our customer decided to replace the old hardware with a ControlByWeb X-410™. They used BASIC script to program the logic, counting the runtime hours and setting an internal register to indicate which pump needed to take the lead, and which needed to be the lag role. Our IoT logic controllers are perfect for load balancing pumps.

Determine the best products for your application with our Sales Engineers.

Making the Move to an IoT Controller

There are many advantages to switching to an IoT logic controller. You’ll save money, reduce complexity, and build on a platform that gives you the data you need to make more informed decisions. The best thing you can do is contact us to talk it through and help you consider all the implications. Then you can develop a transition plan that works for your application.

Contact us today about your aging control hardware, and how we can help you bring your monitoring and control into the 21st century.

The ControlByWeb® Difference

For help with your industrial application, contact our team or schedule a 15-minute product demo.