Data Center Temperature Monitoring

Ensure your server rooms and data centers stay within optimal temperature ranges with real-time IoT monitoring and control solutions. Whether you’re managing a small server closet or a large data center, maintaining proper temperature and humidity levels is essential to avoid costly downtime, hardware damage, and compliance issues.

Real-Time Data Center Temperature Monitoring

Data centers and server rooms are home to critical infrastructure that must be kept within specific temperature and humidity ranges to avoid equipment failure. IoT-powered temperature monitoring systems provide real-time, continuous tracking, ensuring your IT environment stays within optimal conditions. With edge controllers like ControlByWeb®, temperature and humidity data is captured instantly, logged, and available for review anytime—reducing the risk of overheating or other temperature-related failures.

Temperature & Humidity Monitoring with Email Alerts

Traditional methods of temperature monitoring can leave you blind to sudden fluctuations or extreme changes in your environment. With IoT-enabled systems, your temperature data is updated in real time, enabling immediate action when conditions go outside your predefined parameters. ControlByWeb devices can easily be programmed to trigger email alerts when temperature or humidity conditions move outside of defined thresholds.

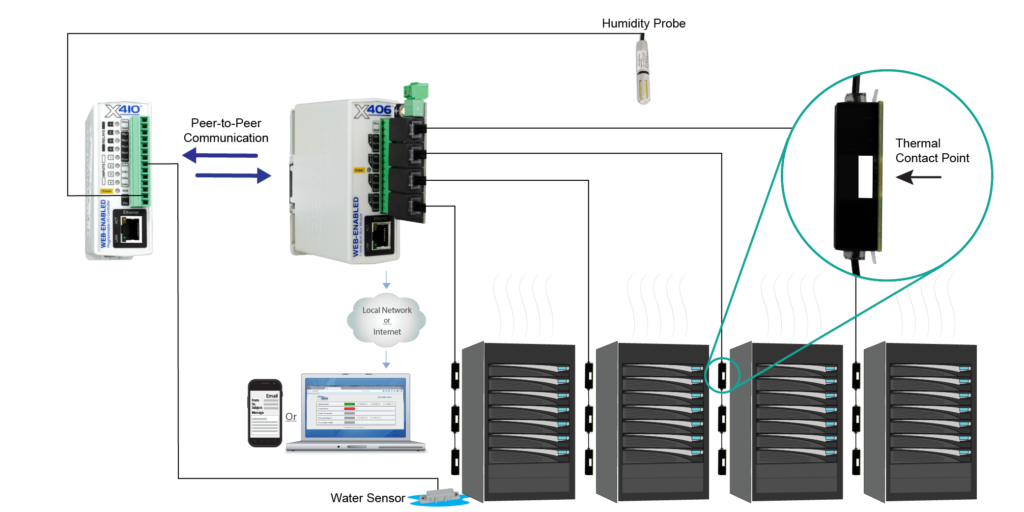

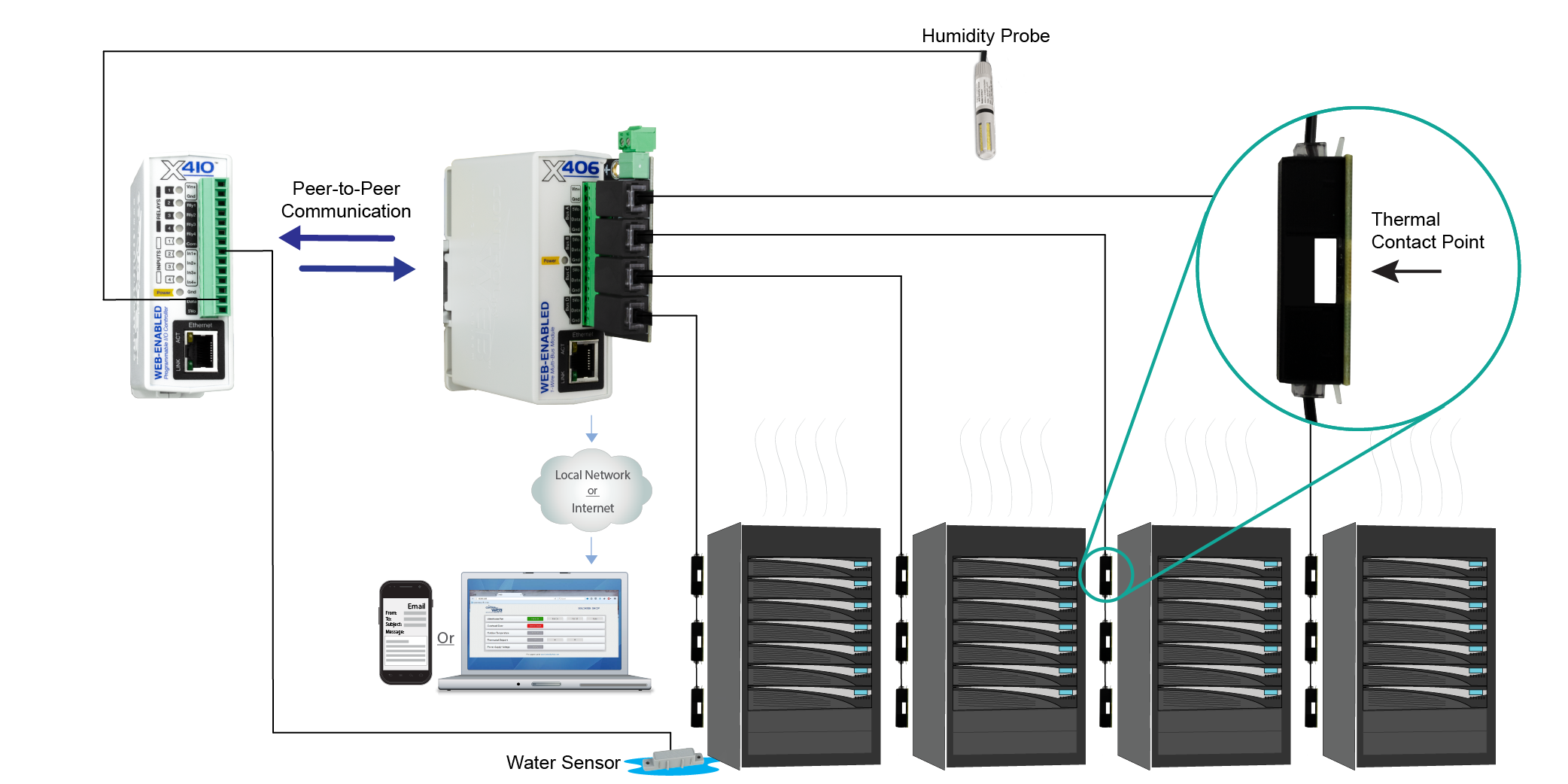

In this example, we see four server racks being monitored with ControlByWeb Quick-Connect Sensors which are wired back to an X-406™. An X-410™ is also being used to monitor humidity with a humidity probe and monitor for leaks with a water contact sensor. The X-410 and X-406 are using Peer-to-Peer communication to talk over the local network.

Recommended Server Room Temperature Monitoring Kit

Determine the best products for your application with our Sales Engineers.

Benefits of Data Center Monitoring with ControlByWeb

Proactive Maintenance and Reduced Downtime

Systems equipped with an IoT temperature monitoring solution have the benefit of proactive maintenance, identifying potential issues before they escalate. Real-time data can reveal patterns that indicate impending failures, such as sudden temperature changes or a smaller fluctuation that lasts longer than a predetermined threshold. Custom logic can be used to avoid false alarms if the temperature falls out of range for within an acceptable amount of time. (Learn more in this support article about eliminating false temperature alarms.)

By addressing these issues early, organizations can prevent costly breakdowns and reduce downtime, ensuring uninterrupted operations.

Simple to Install and Use

One consideration when determining the best way to monitor temperature is complexity. ControlByWeb IoT controllers offer robust features while keeping things simple. For example, the Quick-Connect Temperature Solution (QCS) can automatically be detected when wired to one of our modules. Logic, data logging, and notifications can all be established through the 400 Series embedded UI using drop-down menus and if-this-then-that logic.

Energy Efficiency and Cost Savings

Proper temperature management not only extends the life of your IT infrastructure but also helps reduce energy consumption. By monitoring and adjusting temperature levels in real time, you can optimize cooling systems and avoid wasting energy on unnecessary heating or cooling. This leads to reduced utility bills and a more energy-efficient operation.

Improved Compliance and Reporting

IoT temperature monitoring simplifies compliance by providing accurate and reliable data that can be accessed and reported remotely. ControlByWeb edge controllers can generate detailed logs and reports at a set cadence, ensuring that businesses can demonstrate compliance with industry standards and regulations.

An All-in-One Server Room Monitoring Solution

Near real-time IoT temperature monitoring, powered by ControlByWeb edge controllers, enhances accuracy, efficiency, and compliance across various industries. When it comes to data centers, the ability to continuously monitor and optimize temperature conditions is a game-changer. Here are some of the benefits of using ControlByWeb devices:

- Remote system management: Monitor and manage temperature and humidity data from anywhere in the world. With ControlByWeb devices, you can remotely control cooling systems, receive alerts, and review historical logs without having to be physically present.

- Real-time temperature data: Review current data and historical temperature and humidity logs directly through the browser-based UI. This data can be shared through an API call, a scheduled FTP upload from the device, or through email.

- Ease of use: Controllers feature a browser-based UI with drop-down menus to quickly and easily create conditional and scheduled logic, set email notifications, and more.

- Independent or integrated: ControlByWeb modules feature on-board logic, allowing for I/O control at the edge, plus an open API. This allows them to seamlessly operate independently or as part of a larger system.

- Connectivity: Hardware options allow for Ethernet, WiFi, or cellular networking to be used to share I/O data. This way integrators can bypass physical restrictions or use a connection that’s independent from existing networks.

- Redundancy: Sensors can be placed at multiple points, measuring ambient air or direct surface contact. They can even monitor external components, such as exhausts.

- Scalable: ControlByWeb controllers can communicate through P2P networking to share I/O and link remote inputs and relays, allowing your monitoring system to expand as your infrastructure grows.

- Quality: ControlByWeb products are produced in-house at our office in Northern Utah using quality components. They’re backed by a 5-year warranty.

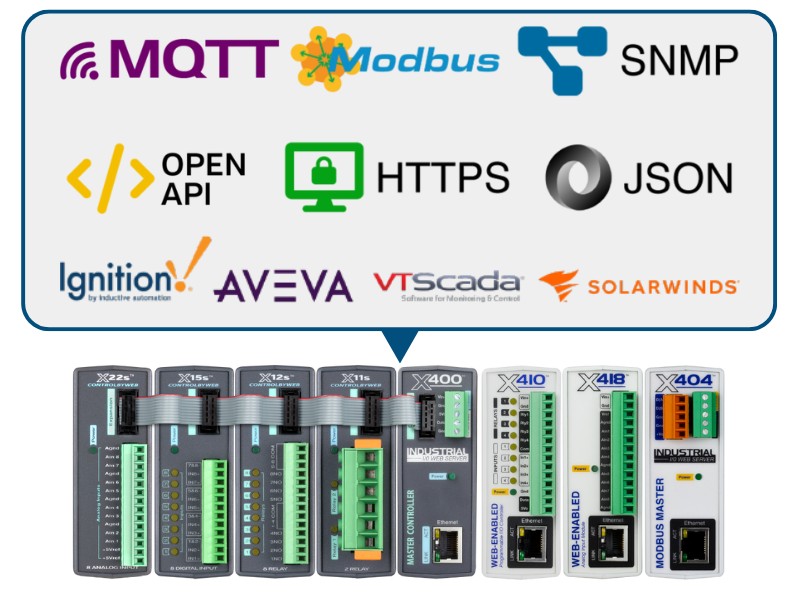

ControlByWeb® IoT Controller Features

Real-Time Temperature Email Alerts

Configure the modules to send timely email and text alerts when a preset temperature is reached.

Remote Monitoring

Capture and share edge data of a freezer or greenhouse and share it through Ethernet, WiFi, or LTE-M cellular networking. See available cell plans.

Open REST API

Use common languages like SNMP, HTTP, MQTT, and Modbus to integrate with virtually any third-party system. Learn more about our open API.

I/O Control Based on Temperature Sensor Data

Build conditional and scheduled logic without code to trigger alarms, heaters, fans, and more through simple drop-down menus, thanks to our Task Builder.

Log Temperature Data

Track temperature, humidity, and other metrics over time. Graphs can be viewed through the device interface or sent via email.

Expandable I/O

Devices like the X-600M can be enhanced with expansion modules that bring additional I/O capability.

Test the Platform

We’re confident that you’ll find our embedded UI simple to navigate and program. Click the button below to access a live controller running here at our office in northern Utah. You can set up I/O, create logic, see the state of relays and inputs, and more.

X-410™ Live Demo

Take a self-guided tour of the built-in firmware included with our best selling X-410.

Use the Setup Page to set up I/O, change settings, and create logic with intuitive dropdown menus.

Use the Control Page to see and change the state of relays and inputs at a glance.

*Setup page login information: Username: admin Password: webrelay

Schedule A Guided Walkthrough

Want a little extra guidance? Schedule a 15-minute guided demo with our sales engineers. They’ll show you how it works for your application.

We offer free demo units to qualified integrators and OEMs, ensuring our controllers are the perfect fit for your application. To be considered, submit a sample unit form for review. We’ll collaborate to determine the best device for your needs.